Sirui Floor

Sirui Floor

manufacture and installation of raised floor

Sirui Floor

Sirui Floor

01

Interior floor laid in the civil engineering and construction completion of the renovation.

02

Ground should be smooth, clean, no debris, no dust.

03

Use of space under the floor, laying cable layout, electrical,water, air ducts and air-conditioning system should be installed before the floor construction is completed.

04

Large heavy equipment, Fixed base completed, equipment installed in the base, the base surface of the floor height should be completed with a high degree of consistency.

05

220V/50HZ power construction site there and water.

• Professional cutting saws; • laser level detector, network laserscanner • Level blisters, tape, ink • suction plate device, adiust nut wrench, screwdriver • vacuum cleaner, broom, mop

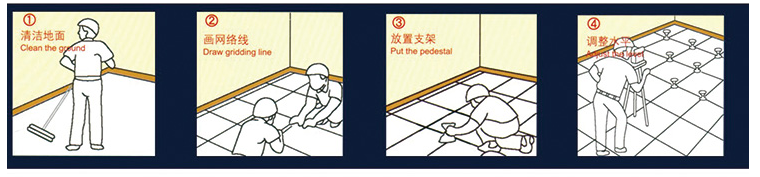

1

Carefully check the surface roughness is found to have significant defences need cal antomation, to party relevantDepartments

2

Horizontal pull, and installation height of the floor playing with theink line to the wall, to ensure that the floor after laying in the same horizontal plane. measure the rooms length width and select thelaying of the reference position. and pop-up stand on the ground positioning grid square intersection of the grid location of the basebracket to ensure the laying of neat, attractive, while minimizing the floor of the cutting.

3

Intersection in the grid position. according to put away support beams. adjusting bracket height. the steel floor beams frame byframe and put into the grid: and calcium sulfate composite floorbeams on the fioor by.

4

If the wall near the floor at the activities of the remaining smaller than the length of the method with the cut and pieced together thefloor, the floor after cutting burr to do in order to avoid staff cuts inthe work place injuries due to tread.

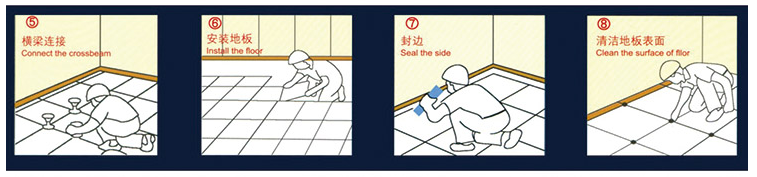

5

In the laying of the floor. block by block with a leveling bubble spirit level, activities by the adjustable height of the floor bearing adjustment process should be laid gently to prevent scratches anddamage to the edge of the floor, laying side edge should also becleaned to avoid to debris, dust left on the floor below

6

Heavy equipment in the engine room set. the device can be installed under the floor of the base stand, to prevent deformation of the floor

7

HPL decorative board processing need to cut or opening. the opening should be made concave corner ended 6-8 hole to preven the processing of the floor after the decorative veneer cracking

Products

About Us

Service Center

Contact Us

Address:No.188, yanzhuang bridge, yaoguan town, wujin district, changzhou

Tel:+86-0519-88726960

Email:sales@czsrfloor.com